We are what we repeatedly do. Excellence, then, is not an act, but a habit

Have you ever thought about how someone rose up to become one of the industry’s greats? We are not talking about those who had a stroke of luck (although, that’s not a bad thing), but those revolutionaries whose ideas, knowledge, skills and hard work shaped and directed the future of doing business. It’s enough to go back in time a bit in order to find interesting examples that set the foundations and became the role-models of a certain industry. So today, we’ll go back to post-war Japan, where a business strategy based on the concept of utmost efficiency of all production processes was developed.

After WWII, Japan’s production was in a crisis, and it was imperative to find a way to get it back on its feet again. A sudden decrease in demand for cars and high production costs destabilized the automotive industry, which affected Toyota as well. By studying the American automotive industry, especially Henry Ford’s production technique, Toyota’s management grasped the possibilities of standardized production and segmenting it to deductible steps. They also noticed how the shelves of the American supermarkets were stocked only after the customers bought the products, which enabled the stores to order the products that were actually sought and to reduce their stocks. Japanese production lacked resources and inventory reduction was just the key Toyota needed to develop its production system, known today as “Just In Time”.

Improvement usually means doing something we have never done before

The concept of “Just In Time” is actually pretty simple: you only produce what is needed, when it’s needed and in the quantities needed. On the other hand, the implementation of the system is not so simple. It takes careful planning, good teamwork, efficient schedule and coherence. And none of it comes easy. Since stocks are reduced to a minimum, a perfect flow of materials needs to be ensured. That is achieved through good cooperation and communication with suppliers. In order to anticipate all the potential delays, it would be ideal to have a larger number of suppliers that are located close to the production facility. They have to be able to deliver the necessary parts in the given time frame and adapt to any changes. Naturally, in order to perfect the production process, it is important to uncover the market’s demands so that you don’t manufacture surplus or unnecessary goods which then become waste.

The most dangerous kind of waste is the waste we do not recognize.

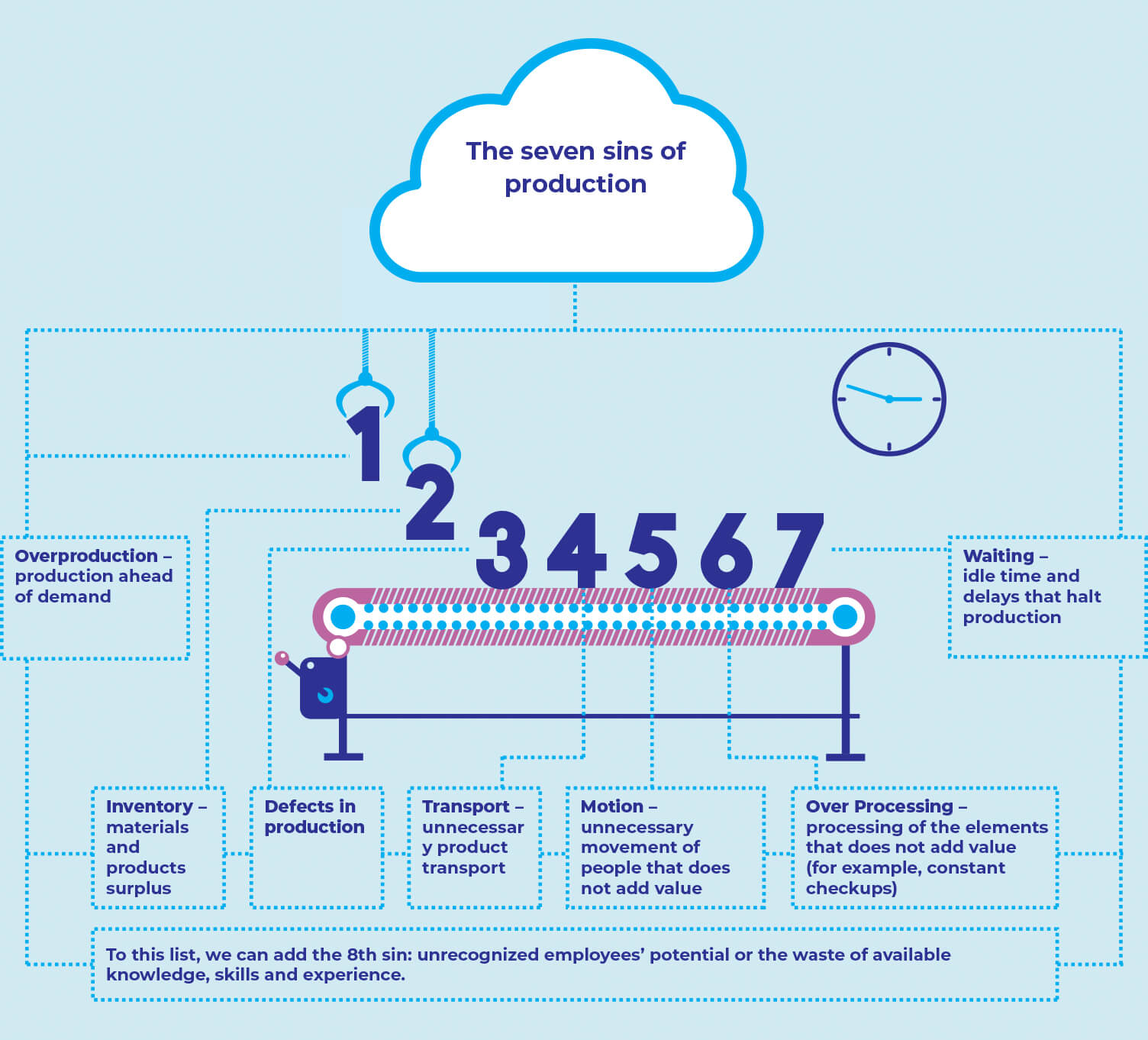

Toyota developed a system based on the total elimination of waste. The waste is defined as everything that does not add value, in terms of time, goods or space. In order to remove the waste, it is very important to recognize it, so that it doesn’t slow down production in later phases. The system has to be flexible enough to adapt to market demands and it is also very important to establish trust between supervisors, employees and suppliers. Although it sounds illusory, harmony within the system is necessary because floundering in one segment affects the final state and the quality of the product. Realising that, Toyota developed another key element of the Just In Time strategy – the autonomation (jidoka) of the production system. To minimize the chances of manufacturing a faulty product, the machines stop as soon as they detect an error and the production continues only after the error is removed.

If you always do what you’ve always done, you’ll always get what you’ve always got.

Toyota is today, without a doubt, one of the industry’s greats. Their success story is a firm evidence of the potential that lies in the Just In Time strategy. Despite the fact that the strategy was profoundly studied and many books were written about it, the fact remains that its implementation is not easy. The notion of the very precise amount of parts that have to be at the right place at the right time in order to start the production is scary enough. Just In Time requires a complete adaptation of work processes and systematic planning but it ultimately leads to an efficient production system that eliminates manufacturing of faulty products (that lead to additional check-ups, complaints and other waste that slows down the production). The costs of production are reduced by investing in efficiency and organizing the supply chain, without raising the price of the products. However, the key to JIT is constant work on the improvement of the process, so that the quality of the parts and the final product remains flawless. Because nobody who craves success should not forget that the price of greatness is responsibility. (Winston Churchill)

Gordan Smadilo, project manager